Position:Home > Company News

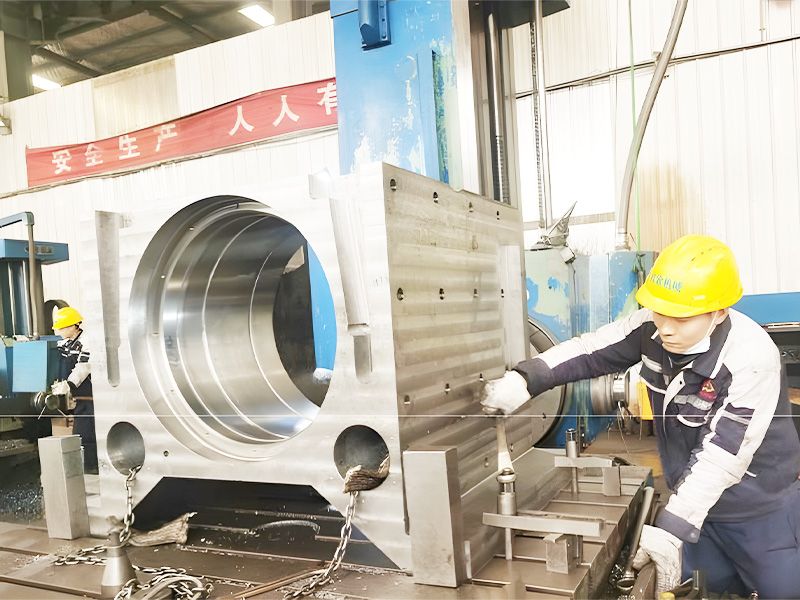

Jiyuan Xinxin Machinery Co., Ltd. is located at No.12, Zone B, Tiantan Entrepreneurship Park, Huling Industrial Agglomeration Zone, Jiyuan City, Henan Province. It was established on December 19, 2013. The registered capital is five million yuan. Company type: Limited liability company (invested or controlled by natural persons). Business scope: Mechanical processing; Sales of steel and components; The import and export business of our company's self operated products. Projects that require approval according to law can only be operated after approval by relevant departments. Jiyuan Xinxin Machinery Co., Ltd. mainly focuses on mechanical processing and has a team of employees with high technical level and professional dedication. The company has advanced process equipment and complete processing equipment, and passed ISO9001 quality system certification in 2020. The company has various models of gantry machining centers, horizontal machining centers, vertical machining centers, boring and milling machines, milling machines, lathes, drilling machines, grinding machines, sawing machines, flame cutting machines and other large-scale equipment to meet production needs and ensure processing quality. Has won a wide reputation in the market, received high praise from users, and has formed a stable customer base. Our company's products such as bearing seats, rollers, and frames have been supplied to Taiyuan Heavy Industry Co., Ltd., Taiyuan Greesen Heavy Transmission Machinery Co., Ltd., Shandong Zhenye Metal Materials Co., Ltd., Hebei Muran Environmental Protection Technology Co., Ltd., Changzhou Dinglong Environmental Protection Equipment Co., Ltd., Shanxi Changfan Heavy Machinery Equipment Co., Ltd., Xi'an Kaiwei Machinery Co., Ltd., Jiangsu Zhongvanadium New Material Technology Co., Ltd Hebei Jianlong Iron and Steel Co., Ltd., Heilongjiang Jianlong Iron and Steel Co., Ltd., Shougang Jingtang Iron and Steel United Co., Ltd., Shandong Iron and Steel Group Co., Ltd., Xinyu Iron and Steel, Wuhan Heavy Industry, Xianggang and other major steel mills in China. The company has strong technical strength, including 5 technical inspectors, 47 production workers, 5 management personnel, and 3 logistics personnel. The established departments include important functional departments such as design, process, quality inspection, and production, ensuring that products meet design requirements and formulating high-quality, high-yield, and low consumption product manufacturing process regulations. The company takes "focusing on technology and providing attentive service" as its core value, and everything is centered on user needs. We hope to meet market demands through unremitting efforts and quality excellence; Faced with increasingly fierce market competition, Jiyuan Xinxin Machinery Co., Ltd. has always attached great importance to technological innovation and technology introduction, and has a clear understanding and grasp of the future. The company focuses on product quality and meets market demand. We believe that through our continuous efforts and pursuit, we can definitely bring more convenience and benefits to our customers!

Release time:2023-12-15

MORE

Henan Shengqihong Heavy Assembly Co., Ltd. is located at No.12, Zone B, Tiantan Entrepreneurship Park, Huling Industrial Cluster Zone, Jiyuan City, Henan Province, with a registered capital of 10 million yuan. Company type: Limited liability company (invested or controlled by natural persons). Business scope: Mechanical processing; Sales of steel and components; The import and export business of our company's self operated products. Projects that require approval according to law can only be operated after approval by relevant departments. The company mainly focuses on mechanical processing and has a team of employees with high technical level and professional dedication. The process equipment is advanced, and the processing equipment is complete. It has passed ISO9001 quality system certification and environmental system certification. The company has various models of gantry machining centers, horizontal machining centers, vertical machining centers, boring and milling machines, milling machines, lathes, drilling machines, grinding machines, sawing machines, flame cutting machines and other large-scale equipment to meet production needs and ensure processing quality. Has won a wide reputation in the market, received high praise from users, and has formed a stable customer base. Our company's products such as bearing seats, rollers, and frames have been supplied to Taiyuan Heavy Industry Co., Ltd., Taiyuan Greesen Heavy Transmission Machinery Co., Ltd., Shandong Zhenye Metal Materials Co., Ltd., Hebei Muran Environmental Protection Technology Co., Ltd., Changzhou Dinglong Environmental Protection Equipment Co., Ltd., Shanxi Changfan Heavy Machinery Equipment Co., Ltd., Xi'an Kaiwei Machinery Co., Ltd., Jiangsu Zhongvanadium New Material Technology Co., Ltd Hebei Jianlong Iron and Steel Co., Ltd., Heilongjiang Jianlong Iron and Steel Co., Ltd., Shougang Jingtang Iron and Steel United Co., Ltd., Shandong Iron and Steel Group Co., Ltd., Xinyu Iron and Steel, Wuhan Heavy Industry, Xianggang and other major steel mills in China. The company has strong technical strength, including 6 technical inspectors, 37 production workers, 5 management personnel, and 6 logistics personnel. The established departments include important functional departments such as design, process, quality inspection, and production, ensuring that products meet design requirements and formulating high-quality, high-yield, and low consumption product manufacturing process regulations. The company takes "focusing on technology and providing attentive service" as its core value, and everything is centered on user needs. We hope to meet market demands through unremitting efforts and quality excellence; Faced with increasingly fierce market competition, Jiyuan Xinxin Machinery Co., Ltd. has always attached great importance to technological innovation and technology introduction, and has a clear understanding and grasp of the future. The company focuses on product quality and meets market demand. We believe that through our continuous efforts and pursuit, we can definitely bring more convenience and benefits to our customers!

Release time:2023-12-15

MORE

A large part of the reason why the bearing seat becomes hot during the entire application process is due to the high temperature of the rolling bearing. Such a situation is very unfavorable for equipment application, and people need to immediately inspect and repair it. The common cause of bearing seat overheating is due to issues with the amount and model specifications of lubricating grease added. In such situations, people need to clean the bearing seat and replace it with new vegetable grease if necessary. Due to the high vibration of machinery and equipment, rolling bearings are prone to overheating. There are also many objective reasons that can cause the bearing seat to become hot, such as high external working temperatures, or higher speeds of centrifugal fans compared to higher education institutions, which can also be caused by machine equipment. When encountering a hot condition in the bearing seat, people should immediately analyze the cause and find solutions to the problem, so as to ensure normal application.

Release time:2023-12-15

MORE

When the cooling cycle is properly applied to the bearing seat, it not only increases the service life of the bearing seat, but also improves productivity. The raw materials for bearing seats are usually all made of bearing seat steel according to various solutions, and even more bearing seat steel often has their application limitations, such as temperature. In the application of bearing seats, if the mold temperature is too high, it is very easy to cause turtle cracks on the surface of the mold core at an early stage. Some bearing seats even have turtle cracks on a large scale before exceeding 2000 mold cycles. Even in the production and manufacturing of bearing seats, due to the high temperature of the bearing seat, the color of the mold core changes. After measurement and even exceeding 400 degrees, such temperatures are very prone to cracking when they come into contact with the cooling agent. The products produced are also very prone to deformation, bruising, and sticking to the mold. Under the condition of applying cooling circulation to the bearing seat, the application of defoaming agent can be greatly reduced, making it difficult for operators to use defoaming agent to reduce the temperature of the bearing seat. Its benefits depend on reasonably increasing the service life of the bearing seat, saving aluminum die-casting cycle time, improving product quality, reducing the occurrence of sticking and pulling aluminum, and reducing the application of release agents; It can also reduce the wear and tear of the top rod and core caused by overheating of the bearing seat.

Release time:2023-12-15

MORE